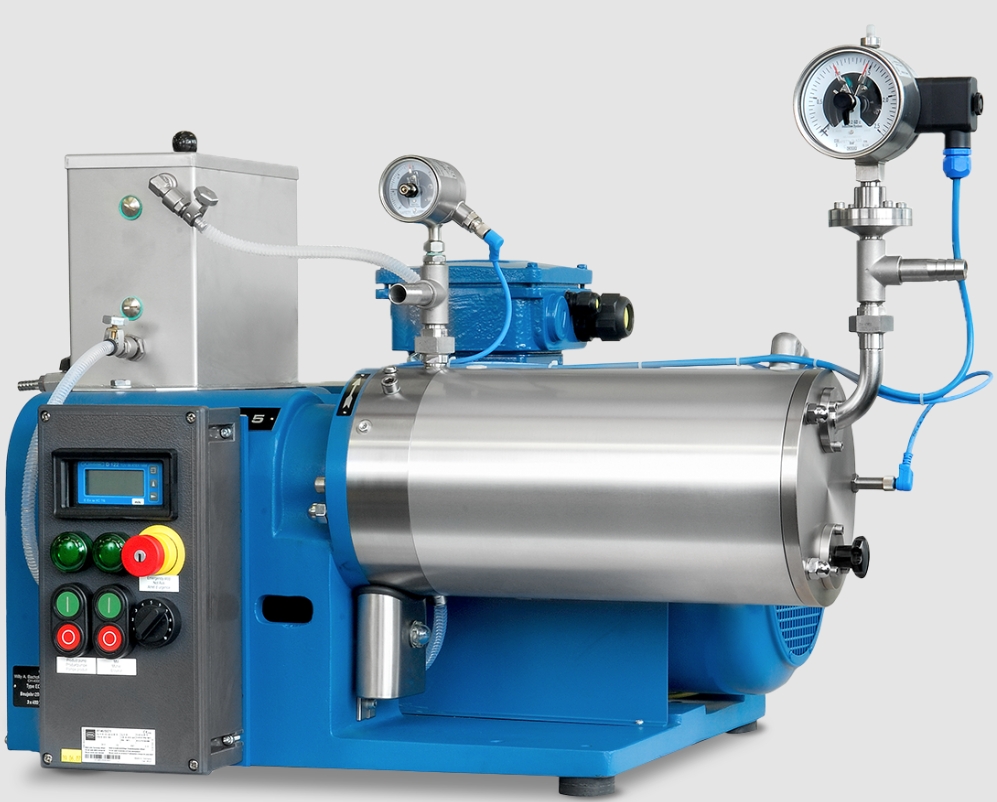

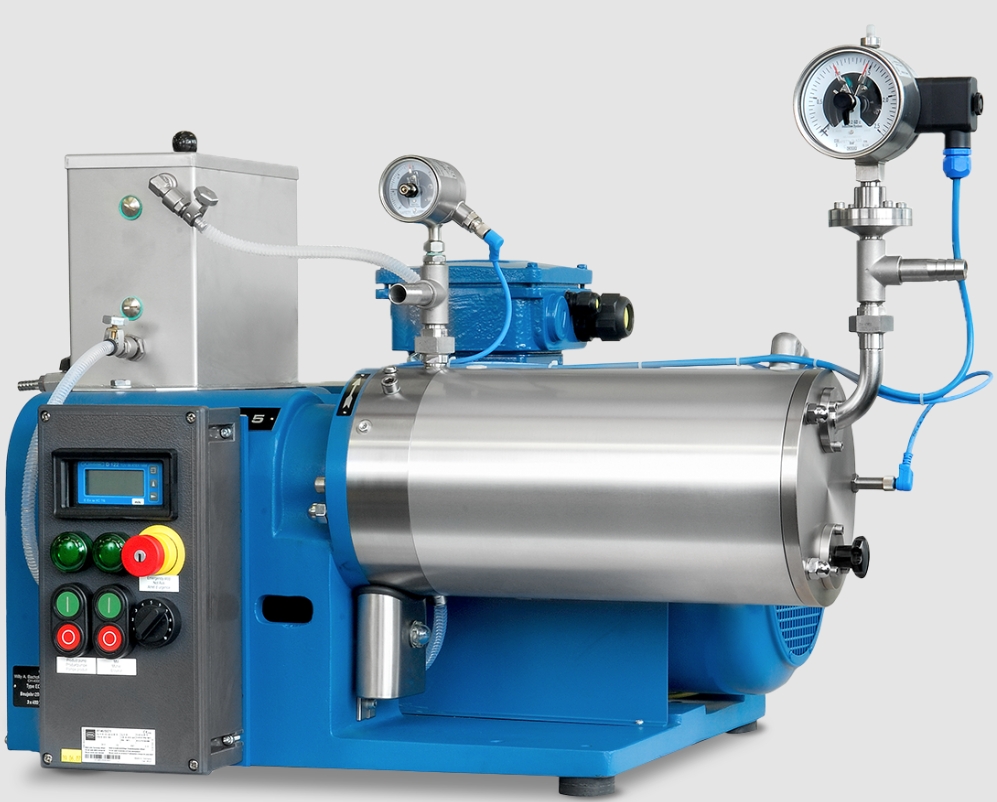

In the realm of chemical processing, the

Grinding Agitator Machine stands as a cornerstone, facilitating the efficient mixing, dispersing, and grinding of various chemical compounds. This versatile equipment plays a pivotal role in a wide array of chemical applications, ensuring precise formulations, optimal particle size reduction, and homogeneous blends. Here are key aspects of its functionality and utility:

**Precise Formulation:** The grinding agitator machine enables chemical engineers and manufacturers to achieve precise formulations by grinding and mixing chemicals with a high level of accuracy. This is crucial in industries such as paints, inks, and coatings, where consistent formulations are imperative for product quality.

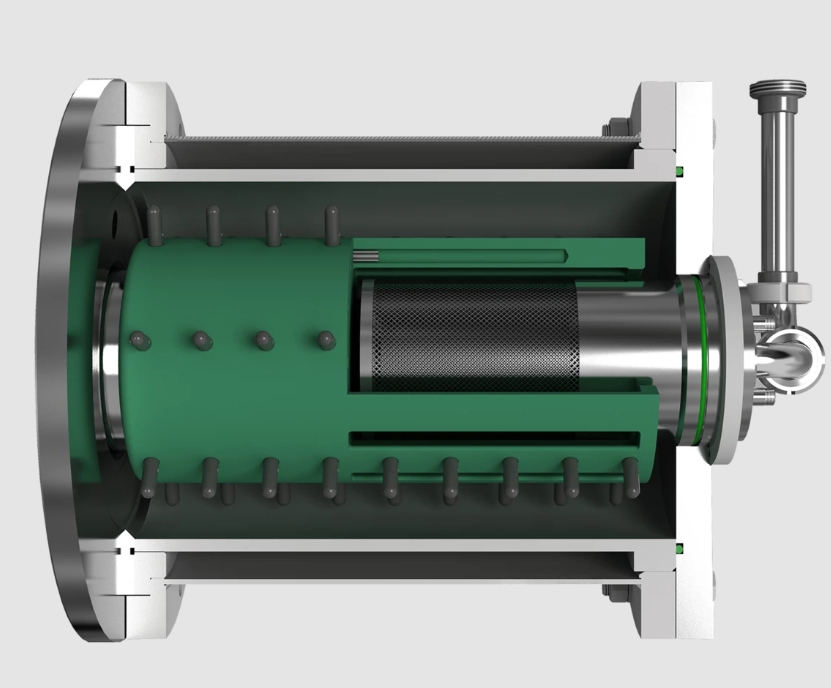

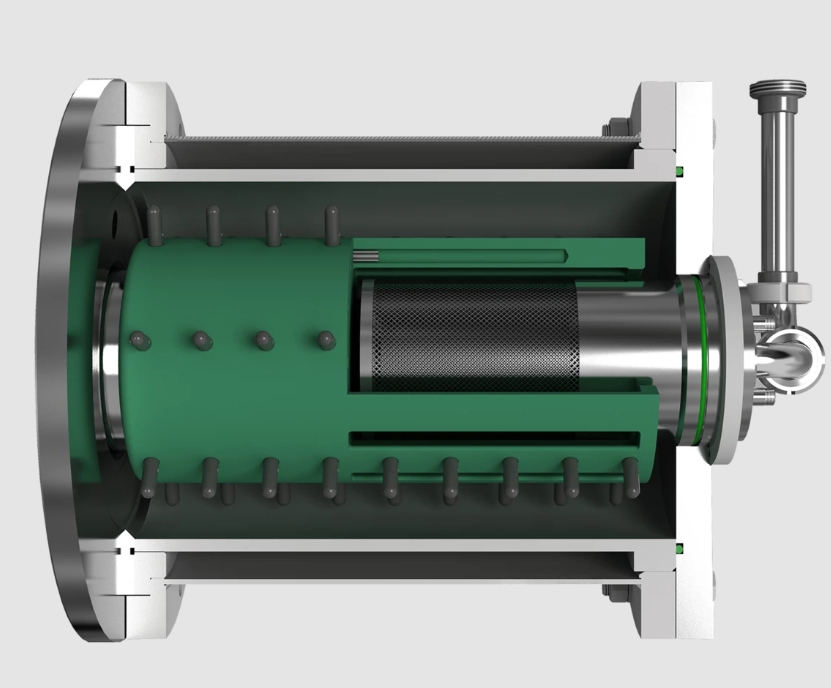

**Optimal Particle Size Reduction:** With its ability to grind materials to specific particle sizes, the agitator machine enhances the efficiency of particle size reduction processes. This is essential for industries like pharmaceuticals and cosmetics, where the size of particles directly impacts product performance and properties.

**Homogeneous Blends:** The agitator machine ensures homogeneous blends by thoroughly mixing chemicals, additives, and pigments. This is critical in applications such as adhesives, where uniformity in composition is vital for adhesive strength and performance.

**Versatile Applications:** From grinding pigments for paints to dispersing additives in adhesives, the grinding agitator machine finds diverse applications across the chemical industry. It is utilized in the production of various chemical products, including coatings, dyes, resins, and specialty chemicals.

**Efficiency and Productivity:** By streamlining mixing and grinding processes, the agitator machine boosts efficiency and productivity in chemical manufacturing. Its automated controls, high-speed operation, and customizable settings contribute to faster production cycles and reduced downtime.

**Quality Control:** The machine supports stringent quality control measures by ensuring consistent results in every batch. This is crucial for meeting regulatory standards, achieving product consistency, and satisfying customer expectations.

**Environmental Considerations:** Modern agitator machines are designed with environmental considerations in mind, incorporating energy-efficient features, waste reduction strategies, and sustainable materials where possible.

In conclusion, the grinding agitator machine is a vital asset in the chemical industry, offering precise formulation, optimal particle size reduction, homogeneous blends, versatility, efficiency, productivity gains, quality control, and environmental sustainability. Its role in enhancing mixing and grinding processes underscores its significance in driving innovation and excellence in chemical manufacturing.